Concept

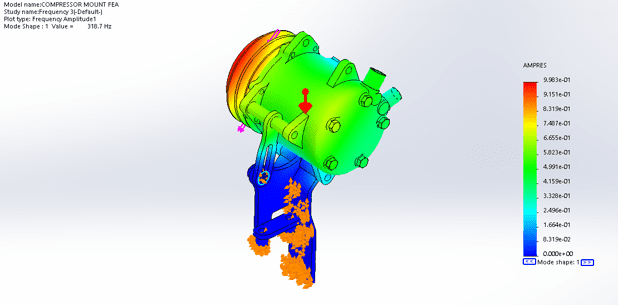

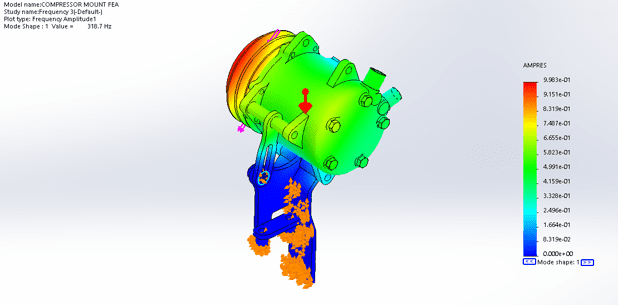

Design

Prototype

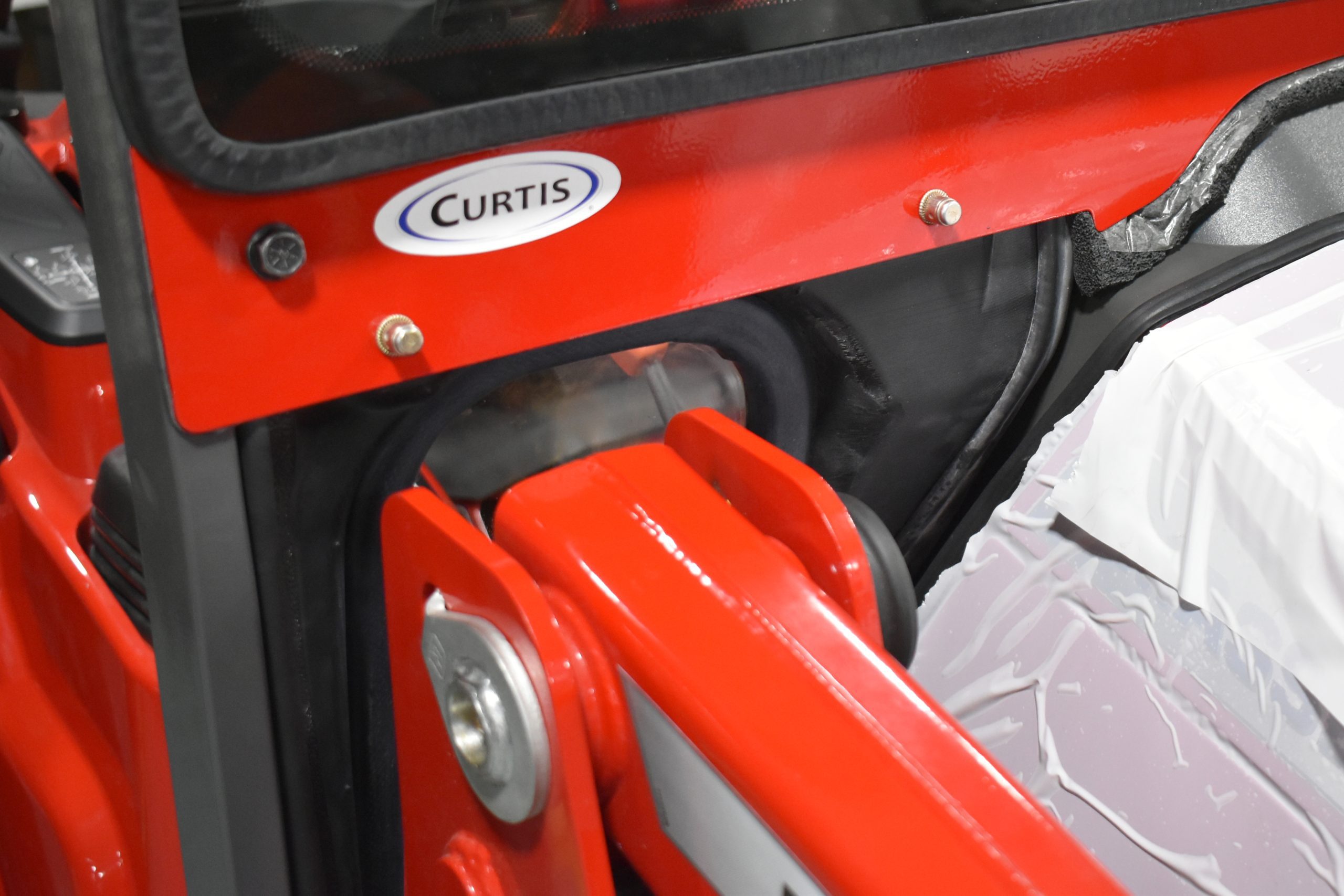

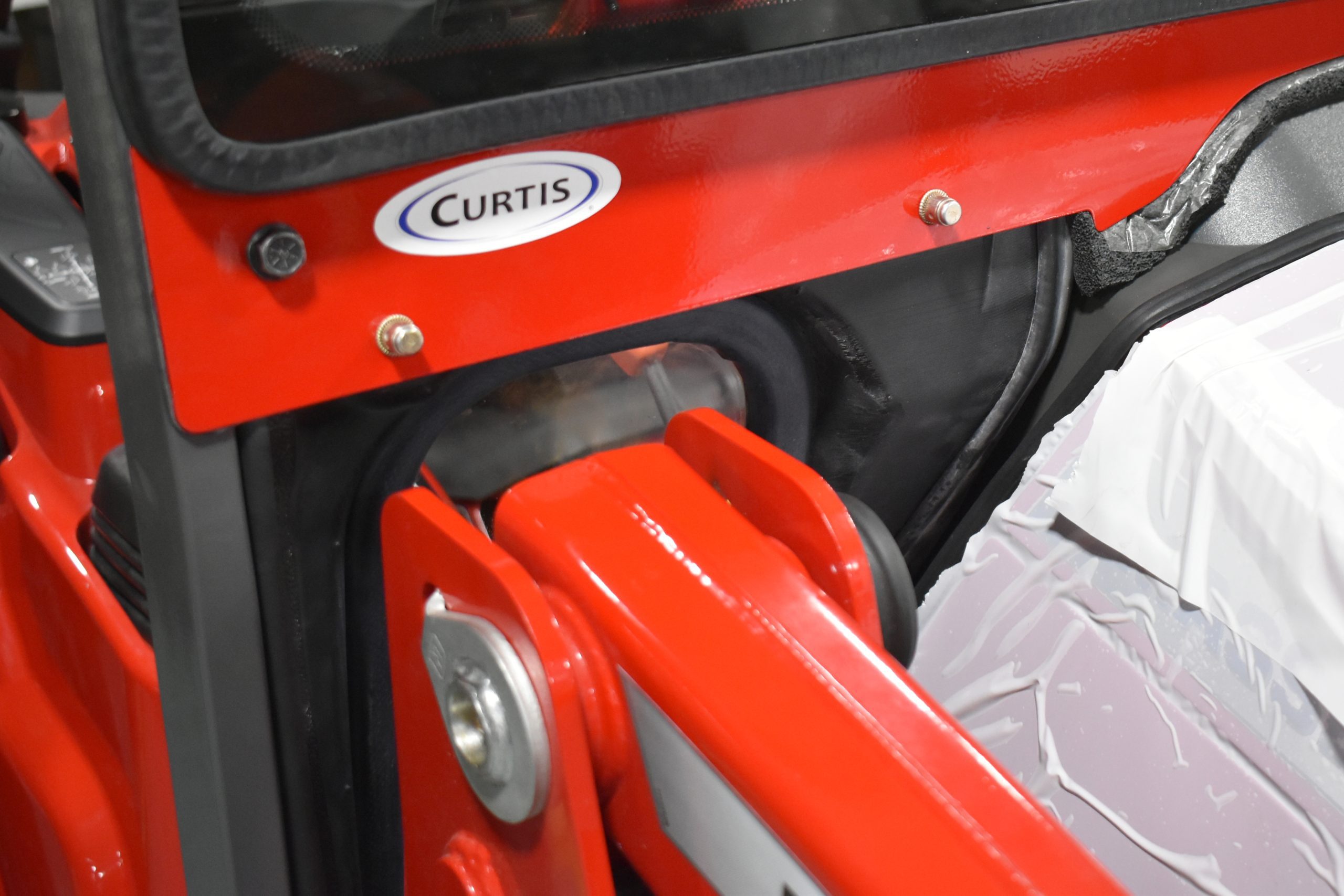

Our focus is on quality and continuous improvement. We manufacture top-of-the-line quality products that meet our customers’ demands for safety and design functionality.

Curtis Cabs, Attachments, and Accessories are manufactured using many different materials including, but not limited to: Steel, Aluminum, Glass (AS1 & AS2), Transparent Plastics, Thermoformed Plastics, Rubber, HVAC, Electronic Componentry, etc.