Metal Fabrication

Welding

Coating

HVAC Specialists

Work with an industry leader that caters to your needs.

Curtis Production Capabilities

Metal Fabrication

Laser cutting

Press brake

Tube bending

- 8,000 Watt Fiber Laser capable of cutting up to ¾”

- Reliable and repeatable part accuracy

- Clean, Oxide-Free Edge for improved powder coat edge adhesion

Multi-Faceted Welding

TIG welding

MIG welding

Laser welding

COBOT welding

- Steel and Aluminum

- Part accuracy through use of welding fixtures to assemble weldments

- TIG welding for structural strength requirements especially in aluminum

- Laser welding offers excellent strength in a small bead where weld size is critical

Electrostatic Powder-Coating

State of the Art Electrostatic Powder Coat Line

Nordson Color Max

- 5 stage pretreatment to prepare parts for powder coating

- 10 automatic guns augmented by 2 manual guns for difficult to reach areas

- Reclaim booth provides efficient use of powder

- Powder Coat exceeds 500+ hours of salt spray testing

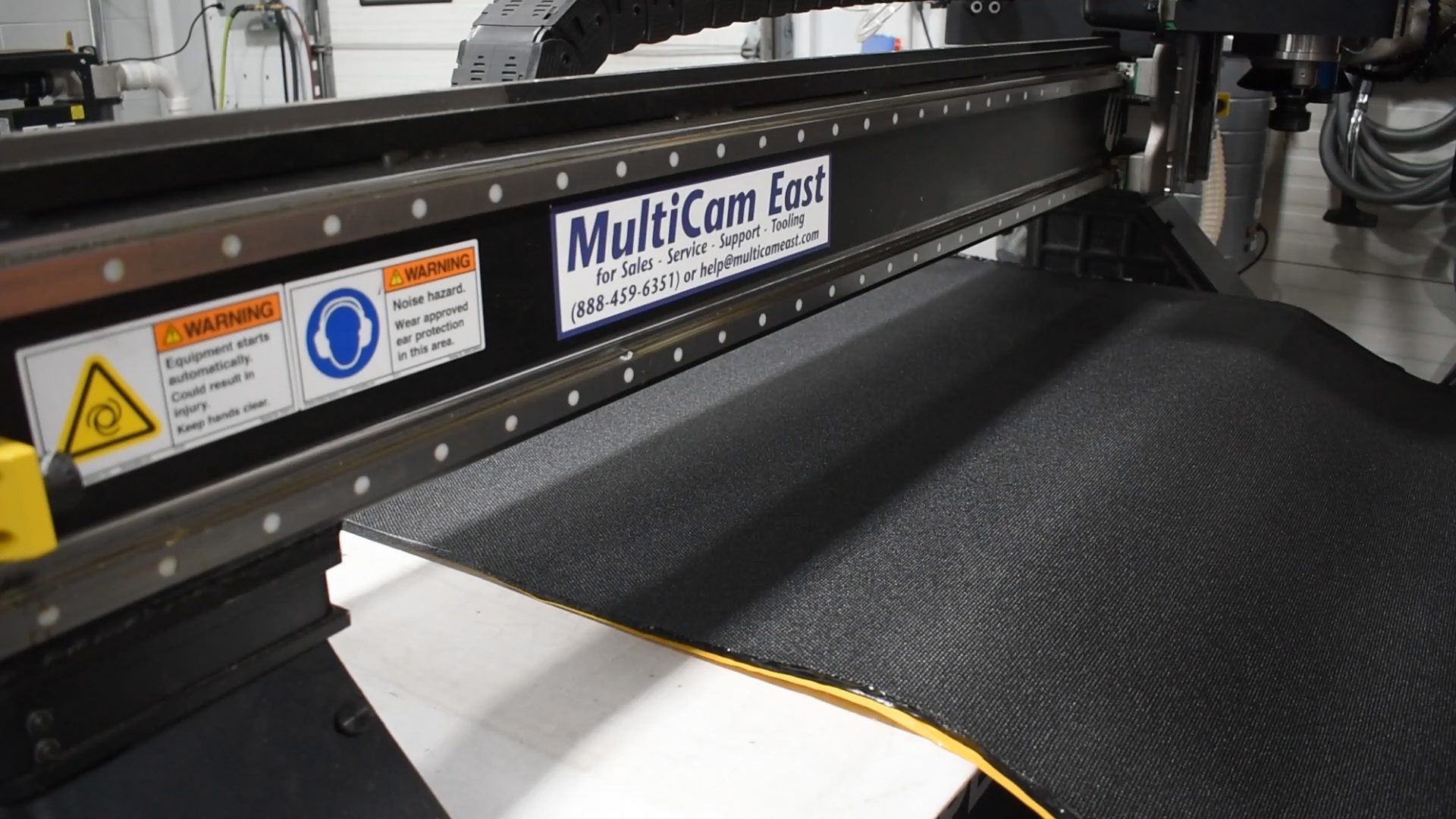

Multi-Cam

Multi-Cam CNC

Apex 3R

- CNC router features router spindle as well as drag and oscillating knife blades

- Rigid materials: polycarbonate and acrylic

- Flexible materials: rubber, vinyl, acoustical headliner, foam

- Accurate and repeatabl;e programmed with MasterCam

Complete Commercial Sewing

HVAC Experts

HVAC Complex Assembly & Testing

Specialized Assembly

Mechanical

Electrical

Industrial Bonding

Hydraulic

Electronic Accessory

Curtis Industries LLC,

Manufacturing Capabilities

State of the Art 165,000 sq. ft. Manufacturing Facility

Laser Cutting

Custom Packaging

Multi-Cam CNC

Hydraulic Components

Plastic, TPO Molding

Commercial Sewing

Heating Componentry

Custom Tube Bending

Metal Fabrication & Welding

Simple & Complex Assembly

Air Conditioning Componentry